Essential Guide to Buying Solenoid Valves for Diesel Engines

The solenoid valve is a crucial component in the functionality of diesel engines, linking various systems and ensuring efficiency in operation. If you're looking to solenoid valve buy, understanding their importance and functionalities in diesel engines is paramount. This guide will provide in-depth insights, making your purchasing decision more informed and beneficial for your engine’s performance.

What is a Solenoid Valve?

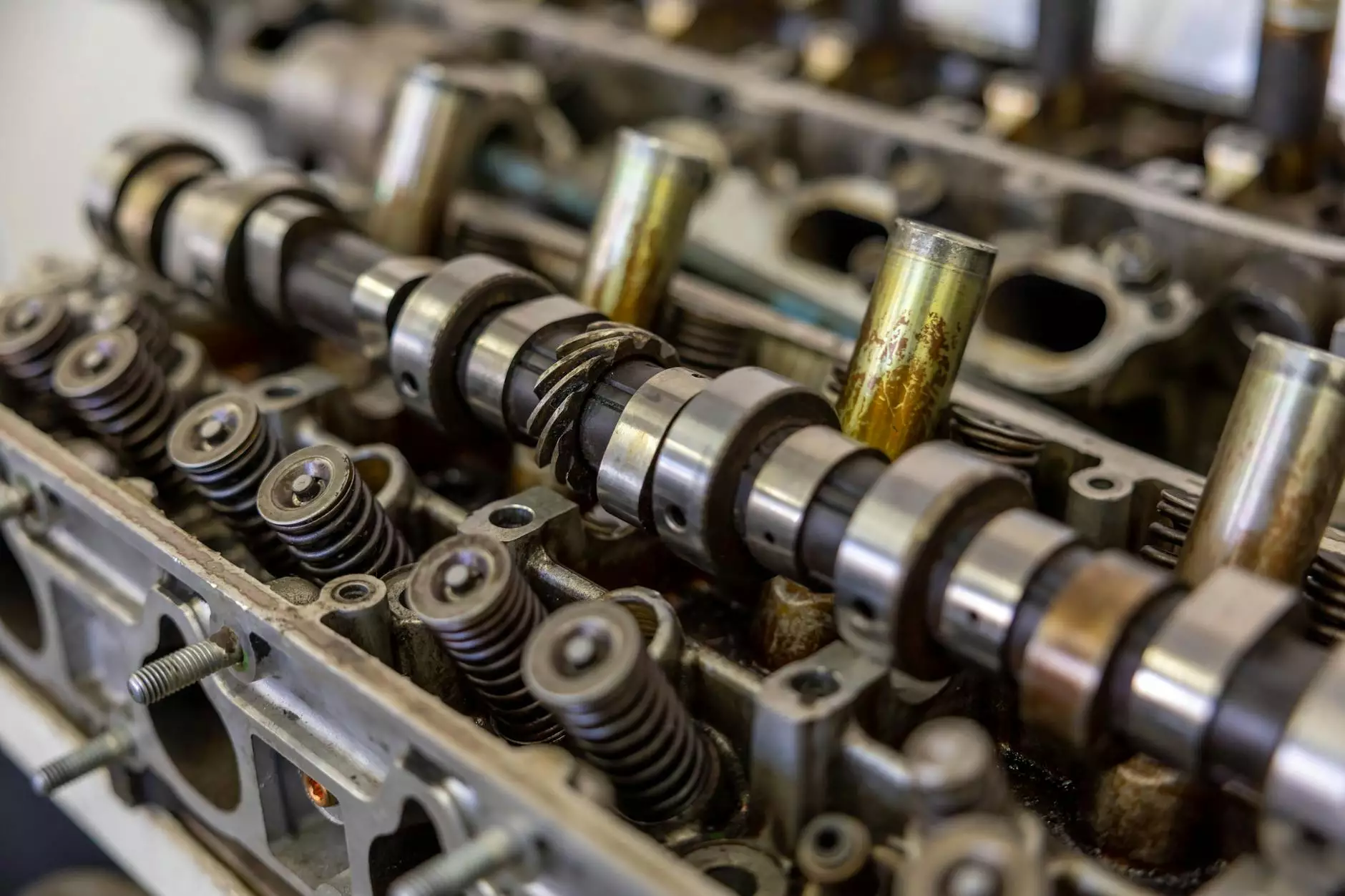

A solenoid valve is an electromechanical device that allows for the control of fluid flow in various applications, including diesel engines. It operates using an electric current to produce a magnetic field that moves a plunger, controlling the flow of fluids such as fuel, oil, and air.

Functions of Solenoid Valves in Diesel Engines

In diesel engines, solenoid valves perform critical functions, which include:

- Fuel Delivery Control: Regulating the flow of fuel to ensure efficient combustion.

- Oil Regulation: Controlling oil pressure and flow for lubrication.

- Air Intake Management: Optimizing air supply for better combustion efficiency.

- Exhaust Control: Managing the release of exhaust gases.

Why You Need to Buy Quality Solenoid Valves

Investing in a quality solenoid valve is essential for maintaining the performance and longevity of your diesel engine. Here’s why quality matters:

- Durable Performance: High-quality valves are built to withstand harsh conditions, providing reliable functionality over time.

- Increased Efficiency: Quality valves enhance the overall efficiency of the engine, leading to lower fuel consumption and improved performance.

- Cost-Effective Solutions: Investing in quality upfront can save you from frequent replacements and repairs in the long run.

Key Features to Look for When You Buy Solenoid Valves

Choosing the right solenoid valve can be overwhelming without the right information. Here are essential features to consider:

- Material: Look for valves made from durable materials such as stainless steel or brass to withstand high pressure and temperature.

- Voltage Rating: Ensure that the valve matches your specific engine’s voltage requirements.

- Size and Connection Type: Choose the correct size and connection type that fits your existing system.

- Response Time: A quicker response time leads to improved engine performance.

- Manufacturer Reputation: Opt for valves from reputable manufacturers known for quality and reliability.

The Importance of Proper Solenoid Valve Installation

Proper installation of solenoid valves is crucial for optimal performance. Incorrect installation can lead to:

- System Leaks: Poorly installed valves can cause fluid leaks, affecting performance and safety.

- Operational Failures: Incorrect alignment or connections can result in valve malfunction.

- Increased Wear and Tear: Malinstallation can lead to premature wear of the engine components.

To ensure proper installation, it’s recommended to consult the manufacturer’s guidelines or hire a professional technician.

Where to Buy Quality Solenoid Valves?

When considering where to solenoid valve buy, it’s essential to choose suppliers that offer quality and reliability. Here are some reputable options:

- Client-Diesel.com: A specialized supplier of diesel engine parts and solenoid valves, known for their high-quality products and customer service.

- Local Engine Parts Distributors: Visiting local suppliers can help you assess the quality of products first-hand.

- Online Retailers: Platforms like Amazon or specialized online stores may offer a wide selection of solenoid valves with customer reviews.

- Manufacturer Direct Sales: Buying directly from manufacturers can sometimes provide better pricing and warranty options.

Tips for Maintaining Your Solenoid Valves

Regular maintenance of solenoid valves is critical to ensure their longevity and effectiveness. Here are some tips:

- Regular Inspection: Check valves regularly for signs of wear, leaks, or damage.

- Cleaning: Regularly clean the valves to prevent blockage and ensure smooth operation.

- Testing: Periodic testing for functionality can help identify issues before they cause major failures.

- Proper Storage: If storing spare valves, keep them in a dry, clean environment to prevent corrosion.

Common Problems with Solenoid Valves

Even the best solenoid valves can encounter issues. Familiarizing yourself with common problems can help in quick identification and resolution:

- Electrical Issues: Sensor malfunctions or wiring issues can lead to improper functioning.

- Physical Damage: Valves can suffer damage from external forces or contaminants.

- Internal Blockages: Dirt or debris can obstruct the valve, affecting its operation.

- Leakage: O-rings and seals can deteriorate over time, leading to leaks.

Conclusion

Understanding the significance and functionality of solenoid valves in diesel engines is essential for anyone looking to solenoid valve buy. Quality valves contribute to the efficiency and longevity of your engine, while proper installation and maintenance practices ensure optimal performance. By choosing reliable suppliers like Client-Diesel.com and adhering to best practices, you can ensure that your diesel engine remains in top condition.